F&P Ø80mm Seamed Downpipe Mill #0266

F&P Ø80mm Seamed Downpipe Mill #0266

Description

Round downspout line with automatic pipe-end reducer for process material: Aluminium, .6mm thick

Rolling speed 45m / minute

New equipment of our design and construction

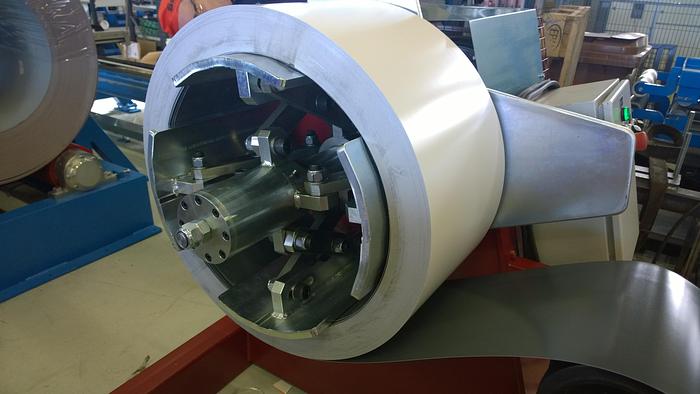

- 2ton Decoiler with pneumatic drum expansion, no coil car

- Mechanical roller tables 2 x 3m

- Cutting and crimping -- hydraulically operated post cutter -- hydraulics 125 bar

Pipe reducer can be selected on/off from control panel. When the function is

on, the reduction is made at the beginning of the downspout and then

forming continues to the programmed length; finally the tube gets cut

Control:

● easy to use programming – the diagram of a product is shown on the screen

● register for 100 standard products

● programmable length in millimetres and parts-amount

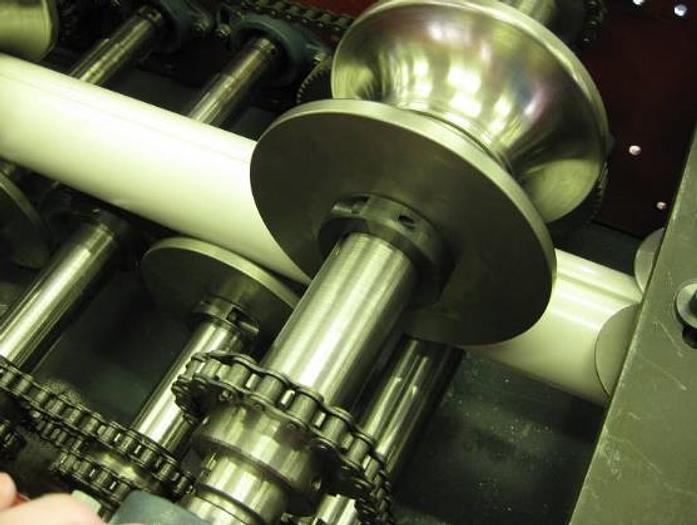

Drive: chain driven with servo motor

El. power requirement: 3 x 400V15kW/63A

Line dimensions x/y/z: appx. 9000mm x 1000mm x 1700mm

Weight: 6t

Terms and guarantee:

according to the Orgalime S 2000

- The equipment fulfils the CE safety requirements

- Light curtains between decoiler and rollformer, and rollformer/stacker are included. Rollforming section is covered with fixed fences on both sides

1. Directive 2006/42/EC on Machinery — meets the essential safety requirements for machinery and equipment

2. Directive 2006/95/EC on Low Voltage Equipment — complies with the safety requirements for low voltage equipment

3. Directive 2004/108/EC on Electromagnetic Compatibility — meets the requirements for electromagnetic compatibility

4. Standard EN ISO 12100 — complies with equipment safety requirements

5. Standard EN 60204-1 — adheres to provisions on machinery safety in terms of electrical equipment

6. Complies with the provisions of EN ISO 13850 standard on machinery safety regarding emergency stops

-

-

Specifications

| Manufacturer | F&P |

| Model | Ø80mm Seamed Downpipe Mill #0266 |

| Condition | New |

| Stock Number | 0266 |