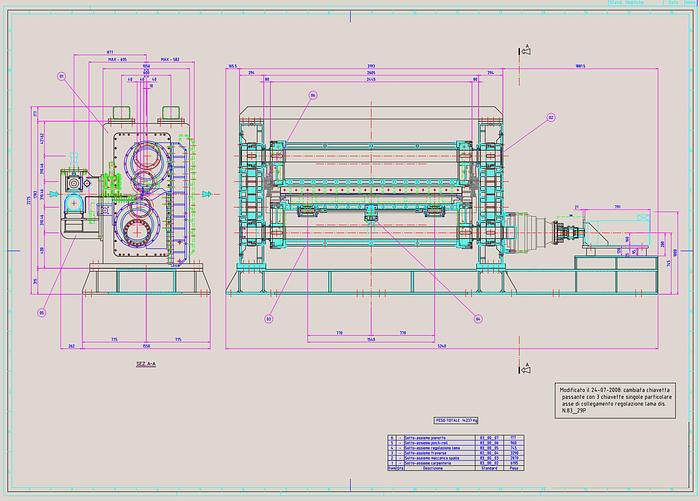

F&P 2100x3mm Rotary Shear #0054

F&P 2100x3mm Rotary Shear #0054

Description

€ 200.000

Built: 2007

Completely revamped by us: 2022

2 year warranty if the machine is re-installed by us

Only the shear and a 4-HI leveler are for sale, of the line shown

The shear and the leveler are off-line, warehoused (they have been replaced to the Customer for him to be able to process higher resistance materials)

Free passage between shoulders 2200mm

.4mm to 3mm R=355 MPa

Line speed max. 40m / minute

+/- .3mm accuracy

140 kW AC motor with inverter

Driving unit dismantled

No control panel

Max. number of cutting cycles 40/minute

Length x max. number of Cuts:

500 mm. 40

1000 mm. 40

1500 mm. 40

2000 mm. 30

2500 mm. 25

3000 mm. 20

6000 mm. 10

The shortest possible part length is 500mm

The lower shear blade is in the shape of a 4-edged parallelepiped, whilst the upper blade is "V" shape with two cutting edges. Quick change of blades. The blade gap is shown on the main control panel (PC)

The machine setting is, always, at same time as the material thickness change and initial-check of a coil

The gearbox is on same frame with the machine; it comes with helical tooth steel gears, hardened and in oil bath

At the machine entrance there are pinch rolls to keep the material stretched towards the shear itself, to optimize the measuring accuracy. The rolls are powered by an AC motor also operating as a clutch

The eccentrics of the blade crossbars are mounted on large bushings and also lubricated in an oil bath, to avoid vibrations during cutting operation and rotation

The process material is passed through in the middle between the two blade holders, which when rotating, have an inter-penetration point corresponding to the cutting area. After the rotation speed of the blades has been synchronized with the advance of the material at a given point (measure), that's all. A significant advantage of this cutting principle is, that the cutting operation takes place simultaneously with the advance of the material preventing the blade from stopping it --- and thus delaying the supply of material

-

Specifications

| Manufacturer | F&P |

| Model | 2100x3mm Rotary Shear #0054 |

| Condition | Used |

| Stock Number | 6046714 |