F&P Linky pro příčné a podélné dělení svitků #4915.cz

F&P Linky pro příčné a podélné dělení svitků #4915.cz

Description

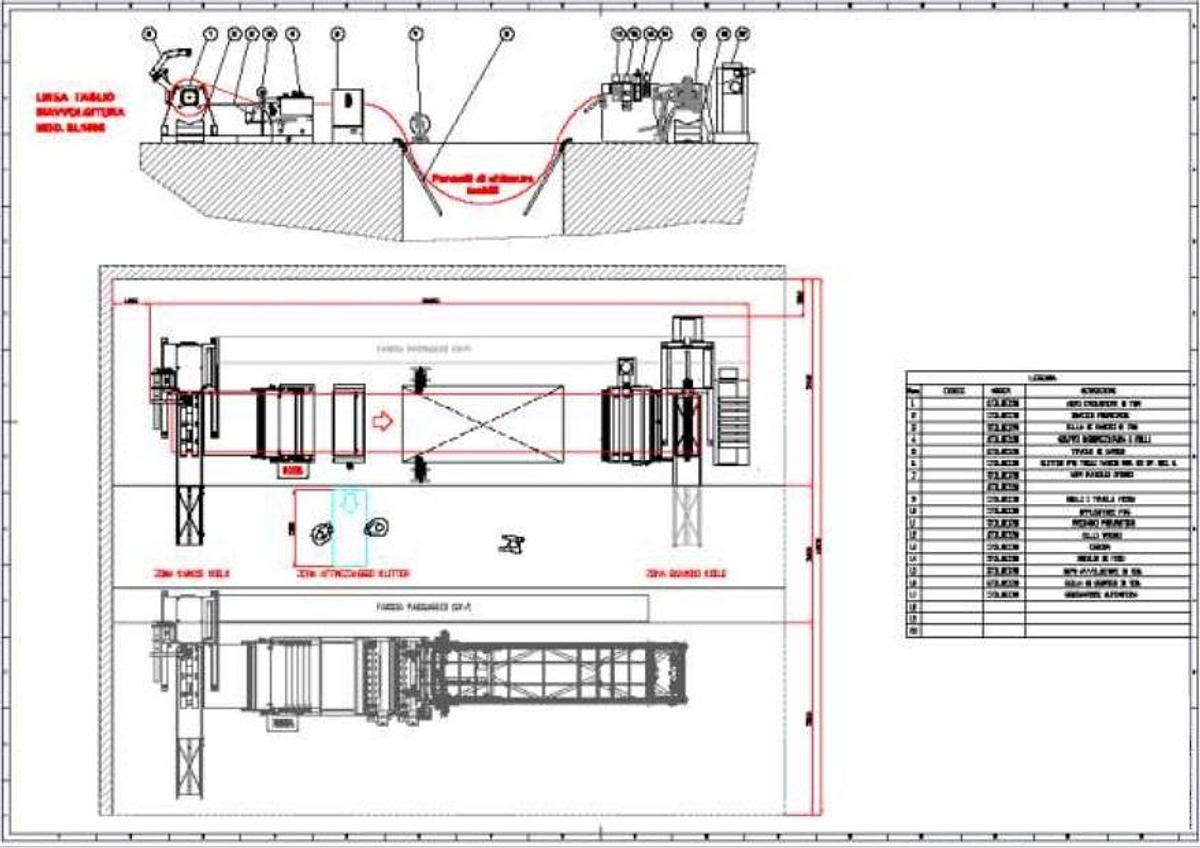

< LT15

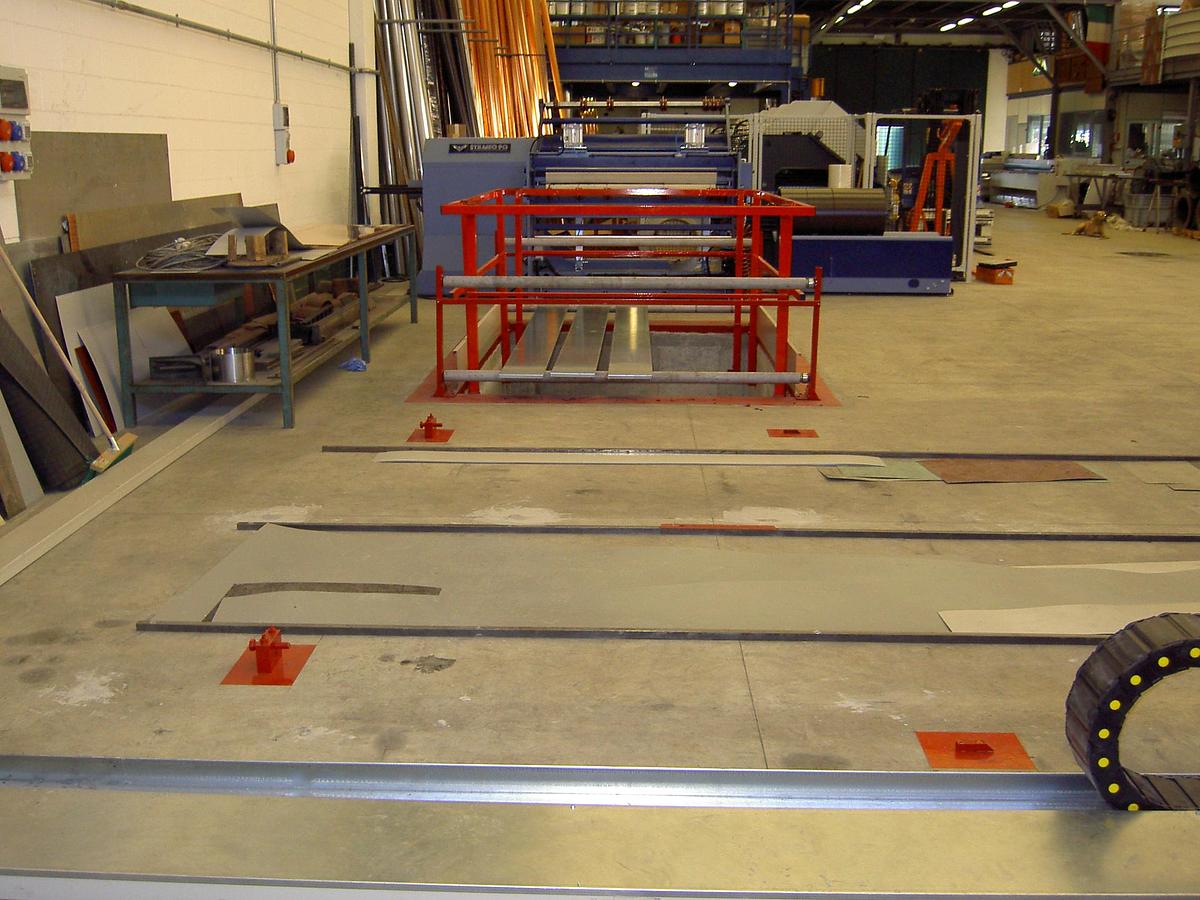

< a) LT25 -- b) 5ton decoiler -- c) tension pad, recoiler and coil off-loading car

< a) various details -- b) example of loop pit equipment -- c) a coiled strip

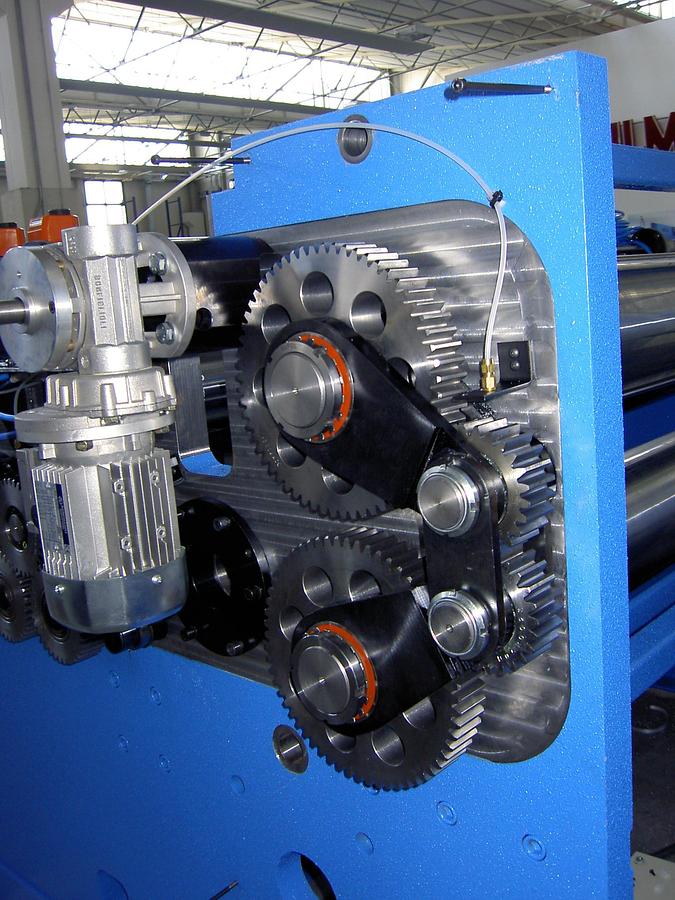

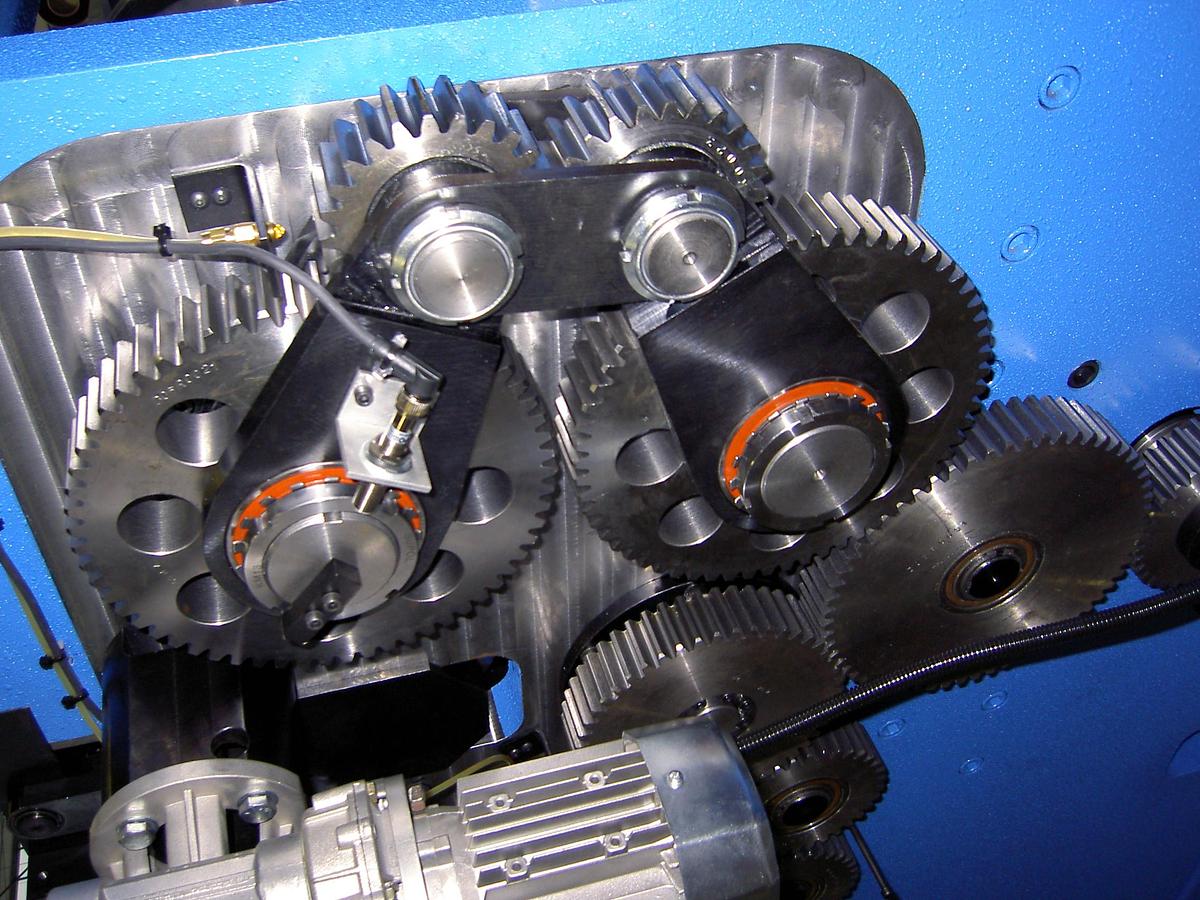

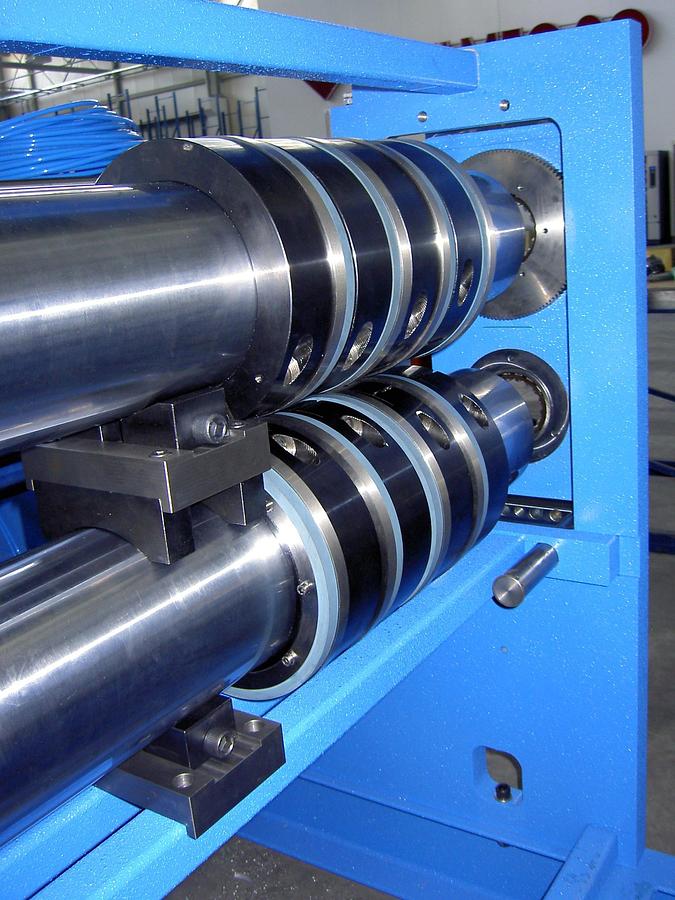

< LT25 details

--- click and then click again to enlarge images --

NEW RANGE

> CUTTING TO LENGTH, SLITTING, OPTIONALLY ALSO: PUNCHING/NOTCHING/RECOILING, STACKING THE PRODUCT...

(SEE ATTACH. AT THE BOTTOM)

Models: LT15 LT20 LT25

all 1500mm wide, .4mm to 2.5mm material thickness (St42)

3 pairs of circular knives "standard", further pairs on request

5ton or 10ton powered decoiler or, alt.: undriven decoiler/s

Speed up to 50m / minute (< LT25)

Options:

- no slitter (= cut to lenght function only)

- material entry auto.- damper, air operated (helpful when using undriven decoiler/s)

- motorized material entry guide (operated by pushbutton or programmable)

- material entry table (which raises and lowers, manually)

- 5 roll or 7 roll straightener (not for LT15; 7 roll type for LT25)

- auto.-lifting/lowering of straightener rolls

- PVC film applicator

- marking system for the fold line

- blanking/notching/punching... units (up to 18) with digital readout

- hydraulic C-frame press with powered transverse displacement (particularly for producing front elements of ventilated roofs)

- additional pairs of circular knives, up to max. 7 pairs in total

- auto. lifting/lowering of slitter knives

- automatic search system for the slitting knife position (the fixing of the tooling is then manual)

- 50kg, 3-30mm scrap winder

- 150kg, mini-recoiler with 600mm mandrel drum for large scrap

- 5ton recoiler with strip tension pad etc.

- loop pit equipment, custom designed (the pit, optional, is 2x4m and 4m deep)

- sheet stacker, custom designed

- powered translation system, placed on a single platform for all the equipment excluding stock reel/s & coil cars

- radio-controller for remote control of the line

LT15

.4-1.5mm

25m / minute max.

Pinch roll brushless motor - power: 4.4kW

Shear motor - power: 3kW

Passline height: 1050mm

Minimum strip width: 65mm

Length accuracy: +/- .5mm

-

Main features:

Two chromium-plated entry rolls and two entry guides, one of which adjustable (by handwheel)

Anti-wear coverings

Two oil-proof-rubber coated pinch rolls. Dia. of rolls 134mm

Slitter head with quick clamp circular knives, with double cutting edge; dia. 120mm shafts, both powered

Mechanical* power guillotine shear with blankholder, blade crearance adjustment by micrometric screws, electro-pneumatic cutch, centralized lubrication, double cutting edge blades treated to also work stainless steel (* Hydraulic shear when the line comes with punching units, press...^)

2006/95/CE & 2004/108/CE and following, compliant

The line is pre-arranged for interfacing with our press brakes and gutter rolls

LT20

.4-2.0mm

30m / minute max.

Pinch roll brushless motor - power: 7.5kW

Shear motor - power: 3kW

Passline height: 1050mm

Minimum strip width: 65mm

Length accuracy: +/- .5mm

-

Main features:

Two chromium-plated entry rolls and two entry guides, one of which adjustable (by handwheel)

Anti-wear coverings

Two oil-proof-rubber coated pinch rolls. Dia. of rolls 134mm

Slitter head with quick clamp circular knives, with double cutting edge; dia. 140mm shafts, both powered

Straightener (optional) with adjustment of upper rolls by one only side of machine

Mechanical* power guillotine shear with blankholder, blade crearance adjustment by micrometric screws, electro-pneumatic cutch, centralized lubrication, double cutting edge blades treated to also work stainless steel (* Hydraulic shear when the line comes with punching units, press...^)

2006/95/CE & 2004/108/CE and following, compliant

The line is pre-arranged for interfacing with our press brakes and gutter rolls

LT25

.4-2.5mm

60m / minute max.

Pinch roll brushless motor - power: 15kW

Shear motor - power: 4kW

Passline height: 1050mm

Minimum strip width: 65mm

Length accuracy: +/- .5mm

-

Main features:

Two chromium-plated entry rolls and two entry guides, one of which adjustable (by handwheel)

Anti-wear coverings

Two oil-proof-rubber coated pinch rolls. Dia. of rolls 180mm

Slitter head with quick clamp circular knives, with double cutting edge; dia. 255mm shafts, both powered

Minimum strip width 100mm (90mm with material thickness reduced by 10%; or 85mm with extra charge). Max. 4 cuts at 2.5mm material thickness, 5 cuts at 2mm, 6 cuts at 1.5mm

Straightener with adjustment of upper rolls by one only side of machine. 7 roll type with 140mm roll diameter.

Mechanical* power guillotine shear with blankholder, blade crearance adjustment by micrometric screws, electro-pneumatic cutch, centralized lubrication, double cutting edge blades treated to also work stainless steel (* Hydraulic shear when the line comes with punching units, press...^)

2006/95/CE & 2004/108/CE and following, compliant

The line is pre-arranged for interfacing with our press brakes and gutter rolls

-

-

Specifications

| Manufacturer | F&P |

| Model | Linky pro příčné a podélné dělení svitků #4915.cz |

| Condition | New |

| Stock Number | 5559047 |