F&P Electric Wire Annealing Furnace #0023

F&P Electric Wire Annealing Furnace #0023

Description

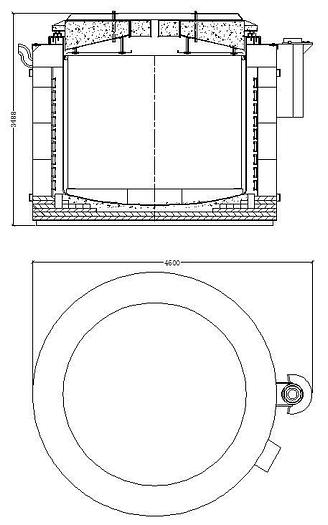

Model: HS-285/220

- Loading dimensions: diameter Φ2850 mm × height 2200 mm

- Rated heating power: 360KW (electric heating)

- Effective loading weight: 12-16 tons

- Annealing temperature: 650-800℃

- Temperature control: automatic temperature control

- Oven temperature uniformity: ≤ ±5℃

- Oven temperature control accuracy: ±1℃

- Circulation fan power: 18.5KW, frequency conversion

- Cooling fan power: 2.2KWx2pcs, frequency conversion

- Rated voltage: 380 V, 50 Hz, three phase

- Oven surface temperature: ≤ 45℃ + room temperature.

Oven body:

• The oven body is welded with high-quality steel plate and reinforced with structural steel, Q235 standard steel with thickness 8mm, the surface has a polishing and cleaning process, spray primer and finishing paint (high temperature paint 300 ℃).

• The bottom of the oven is made of specially shaped bricks and refractory material.

• Have good heat insulation effect, the thickness of the oven wall insulation is 325mm (25t cotton blanket + 300mm module), the heat resistance level is 1260, adopts 25t cotton blanket 25 t (folded) between insulation modules.

Heating system:

• Heating power: three-phase, 380V, 360KW

• Heating method: flat belt heating elements, corrugated type.

• Power Control: SCR (silicon controlled rectifier) heater regulator (0-100%)

• Temperature control: three temperature control sections in the oven, three separate temperature control areas.

• Fixed electric resistance belt: Adopts spiral ceramic screws, can effectively prevent heat loss.

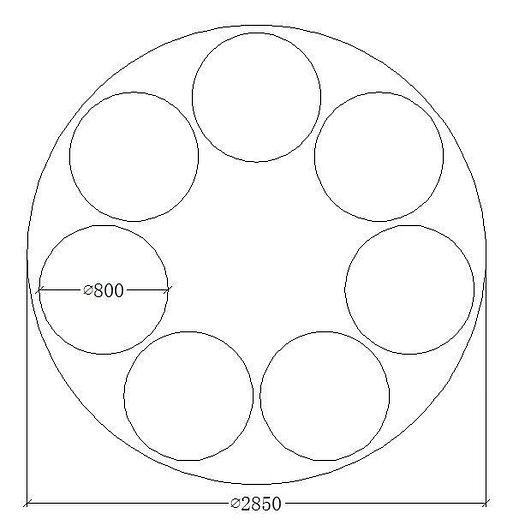

Swaying internal space/”bucket”:

• The inner bucket is made of SUS309S*8mm stainless steel, the round bottom shell lid is made of SUS309S*12mm stainless steel.

• The inner bucket is formed by hyperbolic waveform with high strength and not easy to deform and break.

• The inner bucket adopts lightweight design, can effectively reduce the deformation of the oven bottom.

• The seal adopts a double ceramic fiber base and is equipped with 6-piece manual locking devices.

• Thermal insulation adopts multi-layer cotton blanket, can effectively prevent heat loss.

•The thermocouple tube adopts thickened stainless steel tube, increase the service life.

Guide flow plate:

• The guide plate is made of SUS304*12mm stainless steel.

• Adopts multi-piece circular structure, fewer breaking points, high strength.

• Adopts V-shaped and strengthened structure.

• Increasing the height of the project can effectively promote temperature uniformity in the oven.

Oven Cover:

• The shell covers adopt fluo-forming with lightweight design, can effectively reduce the weight and reduce the corrugation load of the inner bucket.

• The circular upper shell cover material is Q235*6mm, the plate lower shell cover material is SUS304*6mm.

• Internal laying of cotton fiber with 1260 heat resistance level can effectively prevent heat loss.

• The sealing flange and inner bucket can match perfectly and effectively maintain the pressure in the furnace.

• The air inlet pipe adopts thickened stainless steel pipe, increases the service life.

Suspended arm:

• The steel structure adopts sheet steel bending and welding and is reinforced by structural steel.

• The rotating shaft is solid, ensures the strength of the hanging arm.

• Adopt cylinder lifting drive with protection chain, can prevent the oven cover from hitting the oven body when the air pressure is not enough.

• High strength chain can ensure safety.

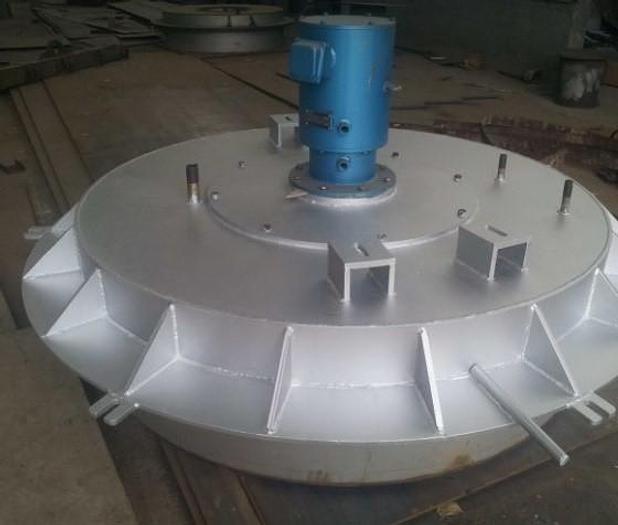

Strong convection hot air circulation system:

• Adopt double water-cooling sealing motor, inverter control, can effectively protect the motor and process regulation.

• Circulating fan power is 18.5 kW, shaft material is SUS310S stainless steel.

• The centrifugal fan adopts Φ700mm long blades, SUS310S stainless steel material, high structural strength.

Strong Cooling System:

• Power: 2.2KWx2 pieces

• High-speed blowing system can ensure rapid cooling.

Electrical control system:

• The basic automatic control system completes all control functions.

• To improve safety and reliability, the automatic control system controllers adopt Japanese Omron PLC, and the touch screen (human-machine interface) is installed on the control panel, easy to operate and can prevent the machine controller error. temperature set in the microcomputer.

• Temperature control: three areas of independent temperature control inside the oven, automatic temperature setting control, over-temperature protection system outside the oven.

• Cooling control system: adopts automatic operation of set temperature, air cooling by fan.

• The main electrical components adopt high quality brand, precise and reliable, long life, easy installation and maintenance.

Control function description:

• SEMIKRON (Germany) is used for the power regulator and temperature control instruments; for overtemperature alarm, and CHINT low voltage electrical components.

• The power regulator can adjust voltage, current and three-phase power. Adopt smart meters as control center, PID automatic setting, high control precision, drive SSR output, achieve optimal temperature control point, setting various parameters, testing and perfect protection function.

It uses LED digital display, keyboard input, easy to use. The input and output interface adopts isolation technology, strong anti-jamming ability. And it adopts independent temperature measurement and control.

• Due to the heating and thermal insulation, a power regulator is adopted, for an intelligent constant temperature. The components have a long life, save energy and reduce consumption, almost no disturbance to the electricity grid.

• The temperature measuring components adopt Taiwan K type 0~1100℃ thermocouples, the +, - matches the temperature controller input, and are equipped with pressure gauges, over-temperature sound and light alarm and explosion-proof device.

• Circulating fan frequency conversion control and powerful cooling fan can effectively protect the motors.

The equipment and materials supplied by the buyer:

Cooling tower (used for circulation fan)

• Junction pressure: 0.1-0.2 MPa

• Cooling capacity: 1 ton/hour

Cooling water

• Content of suspended substances: <10mg/l

• Filter mesh hole: <0.3mm

• The cooling water must not corrode the surface of the equipment, otherwise the buyer will need to provide a set of water treatment equipment.

• Max inlet water temperature: 35℃

Air compressor (used for hanging arm)

• Junction pressure: 0.4-0.7 MPa

• Power: 5HP (piston type)

Nitrogen (as a protective gas)

• Purity: 99.99%

• Dew point: <-60℃

• Oxygen content: ≤ 10 ppm

The reel holders are made of Q235 or SUS304 steel, the manufacturer will send the drawing to the buyer for reference.

The working platform, external piping and cables will be provided by the buyer.

-

Specifications

| Manufacturer | F&P |

| Model | Electric Wire Annealing Furnace #0023 |

| Condition | New |

| Stock Number | 5535044 |