F&P 1500x1.5mm Mini+ Slitting Lines (New) #4379

F&P 1500x1.5mm Mini+ Slitting Lines (New) #4379

Description

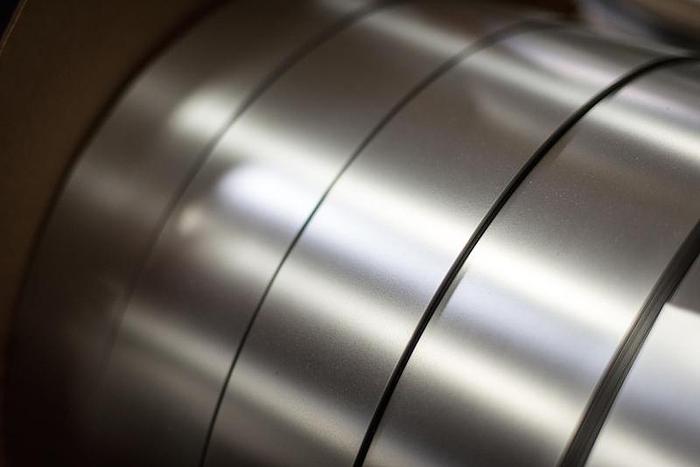

Our "Basic" Slitting & Multi-Blanking* Lines, NEW for 1500mm x .4mm to max.1.5mm (M.S.) coils

(* for use of the line to blank - operation practically possible up to a max. 6m sheet length - with no recoiling: room must be left for a sheet collection table / stacker: that can also, on demand be designed go below floor level when not in use. Such table / stacker obviously implies a supplement to the standard line price for slitting and recoiling only)

Max. 10 cuts at .8mm thickness by the slitter knives

Minimum slit coil width: 60mm Recoiling speed up to 30m / min* with or without loop

(* up to 50m / minute possible as option, but: loop is REQUIRED in this case. -- However, it is suggested to have loop)

Length accuracy at blanking: +/- .6mm -- 3ton Decoiler* & Recoiler

(* option: higher capacity up to max. 15ton, for the decoiler and the coil loading car)

No quick tool change options

Average delivery time for these lines: 150 working days

SEE LINE DIAGRAM IN THE ATTACH., AT THE BOTTOM

SEE --

Line description:

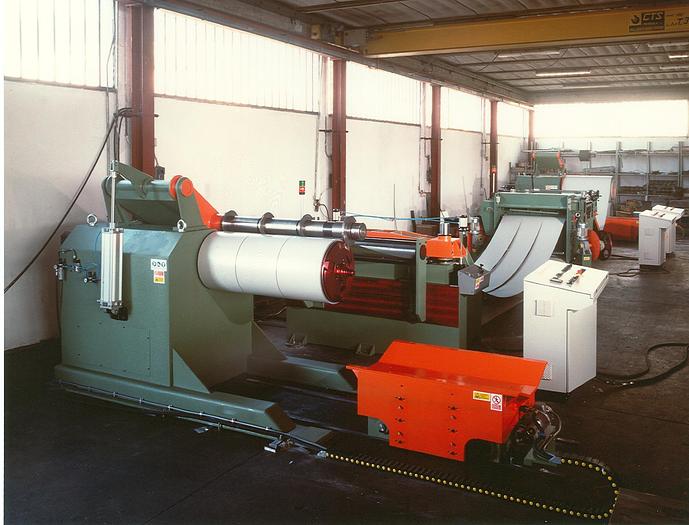

Powered decoiler

of allsteel construction with:

- AC motor, 4kW

- hydraulic drum opening/closing 470-520mm

- 3 mandrel drum segments

- electronic loop control

- air operated strip hold-down

Coil loading car of allsteel construction with:

- hydraulic translation & up-down motion

Hydraulic power pack for decoiler & car ^ with:

- 4kW motor

Coil threading table with:

- max. extension 2.500mm

- 2 hinged elements, raised by air cylinders

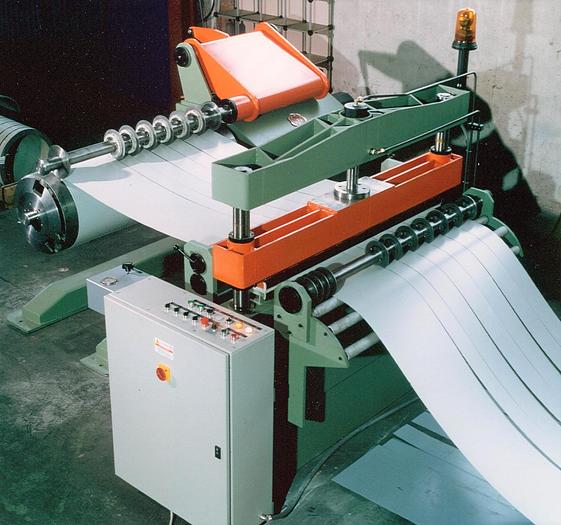

Pinch rolls, straightener, slitter head, mechanical power guillotine shear...:

- material entry guide adjustable on the one hand from control panel, by means of a geared motor. Scrolling on bearings

- two pinch rolls, the upper one covered with rubber; five straightening rolls. All upper rolls adjustable by acting on the one hand, with a series of cranks; decimal positioning-indicators provided. All rolls are of hardened and ground steel. Straightener drive motor: brushless type, 21Nm/3000rpm

- slitter head with 10 pairs of blades

- guillotine shear with 3kW motor

- a removable table is provided to facilitate the slitter tooling exchange operation

Lateral swarf winders

- two, positioned near the guillotine shear; complete with torque limiter reduction unit. Motor power: 2.2kW

Control panel #1 for the above line section ^

- with all electrics push-buttons etc. including the emergency line-arrest button

_

"Combo" strip tension unit with:

- allsteel bridle, whose mobile upper table is operated by hydraulic cylinders; scrolling on two ground steel columns

- strip separation unit complete with adjustable separation rings

- quick-assembly felt pad, air operated

- exit steel rollers to form an 'S' with the material, before it enters the recoilers

Recoiler

of allsteel construction with:

- 3-segment* drum diameter: 500mm - hydraulic drum opening/closing and hydraulic coil edge clamp (< * two segments are fixed and one is mobile)

- air operated overarm and separators

- drive motor: 15kW A.C. -- speed adjustment by a potentiometer placed on the control panel, with the possibility of adjusting the speed both in manual and automatic operation modes)

- traction force control system

Coil off-loading car of allsteel construction with:

- hydraulic translation & up-down motion

Hydraulic power pack for recoiler & car ^ with:

- 4kW motor

Control panel #1 for the above line section ^

- with all electrics push-buttons etc. including the emergency line-arrest button

Safety guarding

The lines comply with CE regulations:

> Direttiva Macchine D.Lgs. 17/10 (2006/42 CE- Direttiva Bassa Tensione D.Lgs. 86/16 (2014/35/UE); Direttiva Compatibilità

Elettromagnetica D.Lgs. 80/16 e194/07 (2014/30/UE)

-

Specifications

| Manufacturer | F&P |

| Model | 1500x1.5mm Mini+ Slitting Lines (New) #4379 |

| Condition | New |

| Stock Number | 4000887 |