COSTA S.S. Sheet Surface Finishing Line #4365

COSTA S.S. Sheet Surface Finishing Line #4365

Description

2100mm x 6mm

TECHNICAL DATA:

- Process Material :

Stainless steel sheets

- Series

200-300-400 with surface finish 2B or BA

- Thickness

.5mm to 6.0mm

- Width x length

2000mm x 550mm

- Feed speed :

3-30m/min

- Direction :

LEFT to RIGHT (from operator side)

- Passline height

930mm

- Compressed air consumption

2 Nm3/h

- Diameter of contact roll

250mm

- Hardness of contact roll

ShA 40 – 45

- Contact roll drive motor

kW 2 x 70 kW

- Diameter of Billy Roll

250mm

- Billy Roll coat

chromed

- Lenght of belt

4600mm

- Cutting speed of sanding belt, max :

30m/sec

- Total air consumption

20.000m3/h

The line speed can be affected by: the quality of material at entry, the finish type, the quality of belts used

The material (sheets) to be of first rate without flatness or surface defects

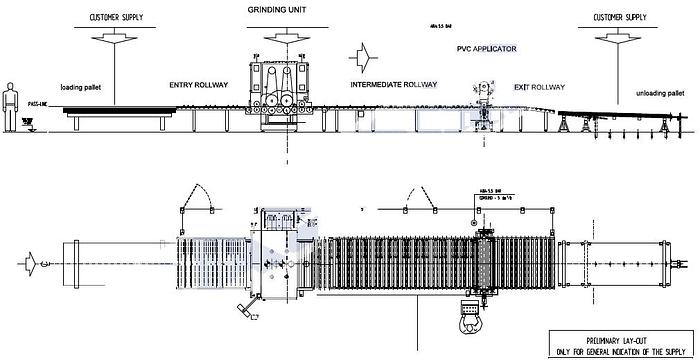

LINE COMPOSITION:

Item 1.1 Entry self-centering roller table

Item 1.2 Two belt grinding machine

Item 1.3 Intermediate self-centering roller table

Item 1.4 Manual PVC applicator

Item 1.5 Exit roller table

^ DETAILS

Item 1.1

- Length

3600mm

- Useful width

2100mm

- Roller coat

PU

- Centering

Automatic in line axis with pneumatic system; pre-positioning by manual and analogue display (SIKO Brand)

- Motorization by AC motor + drive with chain transmission on the shifting rolls

Item 1.2

TWO BELT ALLSTEEL GRINDING MACHINE

- Machine max width

2100mm for the second hand one

- The upper moveble part hoists the belts and their motorisations, together with the controlling pneumatic equipment.

- 2 heads for the belts with emergency pneumatic brakes

- Motorization of heads by AC motor

- Head #1 (entry side) with fixed speed while head #2 (at exit) is with variable speed by controlled from operator panel

- Quick, automatic locking system for both heads

- Support system to insert abrasive belts through pneumatically controlled arm, for lifting and centering belts

- Cleaning of belts during operation by means of an oscillating air jet system, placed on upper part of each grinding head

- Cromed coated Billy Roll, motorized

- Upper structure with motion by means of motor gerboxes, driven by AC motor

- Encoder and display for the machine positioning during the working stage

- The two contact rolls are equipped with an eccentric system for fine tuning during work

- Pneumatic system for the belt tensioning

Belt shifting control system with photo-cells. Possibility of adjusting the system in order to use abrasive belts of different widths

- Belt protection door with electrically-interlocked lock while the machine is operating

- Motorised rollwer table opening by means of cylinders

.

- Each head equipped with double exhausting hood, to be connected to a powder exhausting system

- Cleaning system of sheets by means of air jet units, positioned at the output of the grinding machine

- PLC and operator and drive panels

- Tele-service system for remote assistance

- On-board pneumatic system

Item 1.3

- Lenght :

4000mm

- Useful width

2000mm

- Roll coat

PU

- Centering

Automatic in line axis by means of pneumatic system; pre-positioning by means of manual and analogue display (SIKO Brand)

- Motorsation by AC motor + drive with chain transmission on the shifting rolls

Item 1.4

MANUAL PVC APPLICATOR

- Machine width

2000mm

- Inner diameter of polythene roll

75mm

- External diameter of polythene roll

450mm

- Idle rolls with vertical movement

- The rolls covered by rubber 60 Sh and ground

- Frame with upper support shafts for polytene roll

- Pneumatic locking system of polytene roll with expandable shafts, Quick change system for the expandable shafts

- Top film application

- Pneumatic braking system

- Cutting system for plastic film manual with “hoot wire system” positioned at the output of machine

Item 1.5

- Lenght

3000mm

- Useful width

2000mm

- Roll coat

PU

- Idle rolls

-

Specifications

| Manufacturer | COSTA |

| Model | S.S. Sheet Surface Finishing Line #4365 |

| Condition | Used |

| Stock Number | 3908691 |