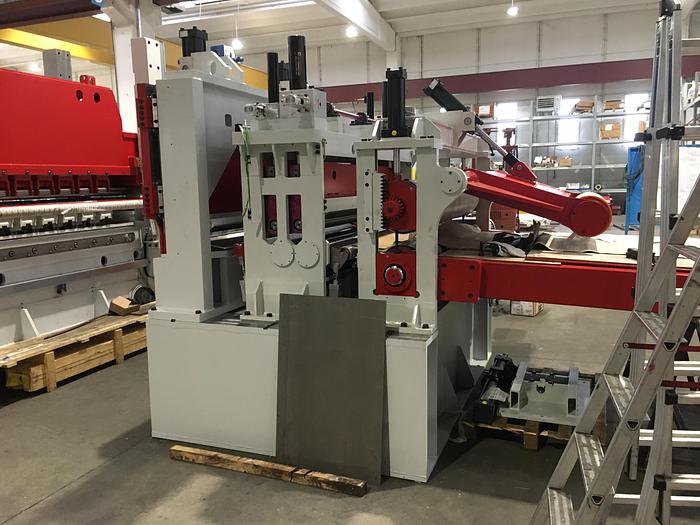

F&P 1600x4mm S.S. CTL Line (New) #4355

F&P 1600x4mm S.S. CTL Line (New) #4355

Description

NEW LINE

(was in stock)

Two 6-HI Levelers

Leveler 1: 17 Roll, Ø62mm (for thickness range: mm 1.5 ÷ 4.0)

Leveler 2: 21 Roll, Ø39mm (for thickness range: mm .4 ÷ 1.5)

+ Entry Tension-Straightener with 2+2 idle rolls

Tensioning Pinch Roll: The Pinch roll can generate a 5000Kg max tension

Line max. speed: 40m / minute

Line direction: right to left

25ton max. coil weight

380V / 50Hz

Material thickness range for tensile strength N/mm² 880:

mm .4 ÷ 3.5

-for tensile strength N/mm² 750:

mm .4 ÷ 4.0

Min. coil width:

mm 400

Max. coil width:

mm 1600

Max. coil weight:

Tons 25

Nominal inside diameter of coil:

mm 508 - 610

Min outside diameter of coil:

mm 900

Max outside diameter of coil:

mm 2000

Min sheet length:

mm 500

Max sheet length:

mm 6000 (3000 + 3000)

Max sheet stack weight:

Kg 5000

Max sheet stack height:

mm 420 (incl. pallet)

Max. line speed:

m/min 40

Length tolerance at constant speed: +/- mm/m 0,20

Line working to: center line

EQUIPMENT LIST

Item 1.1 COIL LOADING CAR, “L-shaped" (ALL ABOVE FLOOR LEVEL)

Item 2.1 MOTORIZED DECOILER ON SLIDING BASE, WITH FRONT SUPPORT TO ASSIST RIGIDITY

Item 2.2 ADDITIONAL SEGMENTS ^ FOR DIAM. 610mm

Item 2.3 EMG SYSTEM FOR AUTOMATIC ALIGNMENT CONTROL – ONE-EDGE DETECTION

Item 2.4 PAPER REWINDER

Item 3.1 PEELER TABLE

Item 3.2 MOTORIZED INTRODUCTION PINCH-ROLLS

Item 3.3 STRAIGHTENING MACHINE 2+2 ROLL

Item 3.4 HYDRAULIC CROP SHEAR & SCRAP BOX

Item 3.5 CONNECTION ROLL TABLE

Item 4 (ROOM TO ALLOW FOR FUTURE INSTALLATION OF EDGE TRIMMER)

Item 5.1 LEVELLER #1 / 17 ROLL – Ø 62 mm – 6-HI Type

Item 5.1.1 ^ ROLL CASSETTE EXTRACTION SYSTEM, MANUAL TYPE

Item 5.2 FELT CLEANING UNIT for 5.1 and 5.3

Item 5.3 LEVELLER #2 / 21 ROLL – Ø 39 mm – 6-HI Type

Item 5.3.1 ^ ROLL CASSETTE EXTRACTION SYSTEM, MANUAL TYPE

Item 5.4 TENSIONING MOTORIZED PINCH ROLL (SLAVE)

Item 5.5 PVC COATER with 3 ROTATING UPPER MANDRELS

Item 5.5 PAPER APPLICATOR

Item 6.1 MECHANICAL FLYING SHEAR

Item 6.1.1 INTER-PENETRATING CONVEYOR

Item 7.1 CONVEYOR AT SHEAR EXIT. TO COLLECT SHEETS

Item 7.2 DEFLECTING BELT CONVEYOR

Item 7.3 FORWARDING BELT CONVEYOR TO STACKER

Item 7.4 SCRAP CARRIAGE

Item 7.5 AUTOMATIC STACKING UNIT – DOUBLE STATION (2x3000 – 1x6000)

Item 7.6 HYDRAULIC PLATFORMS WITH TRANSVERSAL EVACUATION + CHAIN SHUTTLE + CHAIN CONVEYOR with WEIGHING DEVICE

Item 8.1 PNEUMATIC PLANT

Item 8.2 HYDRAULIC PLANT

Item 8.3 ELECTRIC PLANT

Item 8.4 TELEASSISTANCE SYSTEM

Item 9 SAFETY FENCES ACCORDING TO “CE” STANDARDS & GUIDELINES

-

-

Specifications

| Manufacturer | F&P |

| Model | 1600x4mm S.S. CTL Line (New) #4355 |

| Condition | New |

| Stock Number | 3733519 |